Enviroflo Engineering Bag Filters

Dust Suppression systems although very effective in a number of applications are not suitable for example where dust is required to be removed from the process, where strict legislation exists for dust levels in close proximity to the plant or within buildings and in applications where the addition of any degree of moisture is not permitted. Bag filters are also used for the recovery of precious metals in some ore handling applications. A bag filter could be regarded as an oversized vacuum cleaner. Extraction points are fitted to the process at strategic locations where dust is emitted to atmosphere. The use of bag filters requires the process to have a high degree of sealing in order to try to maintain the various conveyors, screens, chutes, etc under a slight negative pressure thus preventing the release of dust to atmosphere. The degree of sealing necessary plus the capital and operating costs of bag filters makes this dust control solution considerably more expensive than Dust Suppression.

Enviroflo Engineering manufacture two specific designs of bag filter:

Both Enviro Reverse Air and Enviro Pulse Jet Bag Filter Systems operate in a similar manner - the difference being the method of cleaning the bags.

Example of Screenhouse handling limestone aggregates. Dust extraction and Dustfoam suppression are being used to control dust

It is important to decide how the dust from bag filters is handled bearing in mind that it is in very dry fine form and the off loading from a hopper below the filter into an open vehicle for example would almost certainly be prohibited. If the dust can be reused then it can be blown into a remote silo and treated separately or in the case of asphalt plants used as a filler in the bitumen mixes. If the dust is required to go to waste then it can be passed through a pug mill/Dust Conditioning unit where water is added in a controlled amount to produce a consistent damp product having a moisture content of some 10%. This can be off loaded into a lorry or dumped onto ground to be removed later by loading shovel for disposal in a suitable tipping area.

In addition to adopting bag filters in association with minerals handling Enviroflo Engineering also provide either Reverse Air Filters or Pulse Jet Filters for Asphalt and Bitumen coated material plants. The bag filter is applied to the rotary dryer together with a number of fugitive dust points on the Asphalt process. This application requires special high temperature bags and a comprehensive knowledge of the workings of this particular process.

Enviroflo Engineering are experts in this technology and have numerous applications over a broad range of asphalt plants.

Enviro Reverse Air Filter on aggregate screenhouse

Enviro Reverse Air Bag Filter (For collecting dust in the dry form)

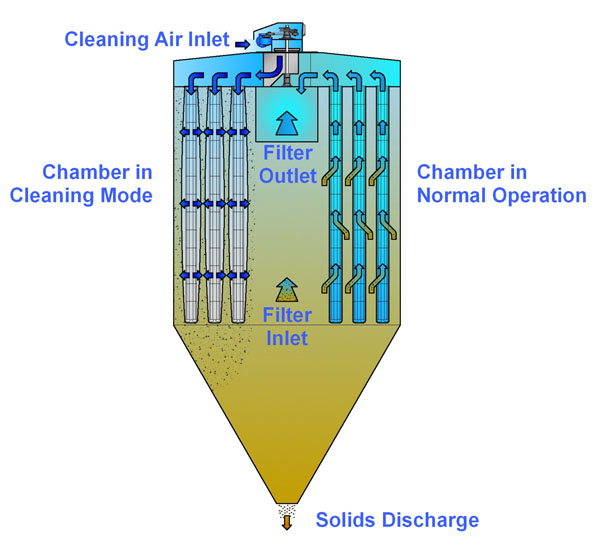

Dust laden air enters the filter at one end and distributes throughout the filter body and around the fabric bags.

Due to the vacuum created by the exhaust fan, the air passes through the porous filter bags leaving the dust on the outside.

The cleaned air passes up through the inside of the bags into a number of top chambers and down through one or more plenum openings into an internal outlet duct and hence via ducting/stack to the exhaust fan to atmosphere. A mechanically driven duct (plenum), open to the atmosphere at one end, is positioned in each plenum opening and this remains at rest during normal running. No cleaning air passes to the filter in this position.

During the cleaning cycle, one plenum starts to rotate and indexes around each top chamber in turn causing atmospheric air to enter the clean side of the filter and pass down into the bags in the reverse direction to normal flow. This reverse air causes the bags to flex outwards thus disturbing the dust cake on the outside. The agglomerated dust falls down into the collecting hopper below. The hopper can be of the trough type fitted with a pneumatic conveying system to blow the dust to a remote silo or fitted with a pyramid hopper for storage and future disposal of dust.